Understanding Zinc Coating Layers and Symbols (Z, AZ)

Zinc coatings are typically specified using symbols such as Z (pure zinc) or AZ (aluminum-zinc alloy). These symbols represent not only the coating type, but also the protective mechanism. Pure zinc provides sacrificial protection, while aluminum-zinc coatings combine barrier protection with sacrificial behavior.

Common coating mass designations like Z100, Z180, Z275 or AZ150, AZ185 indicate the total coating weight applied to both sides of the steel sheet and are directly linked to expected corrosion resistance.

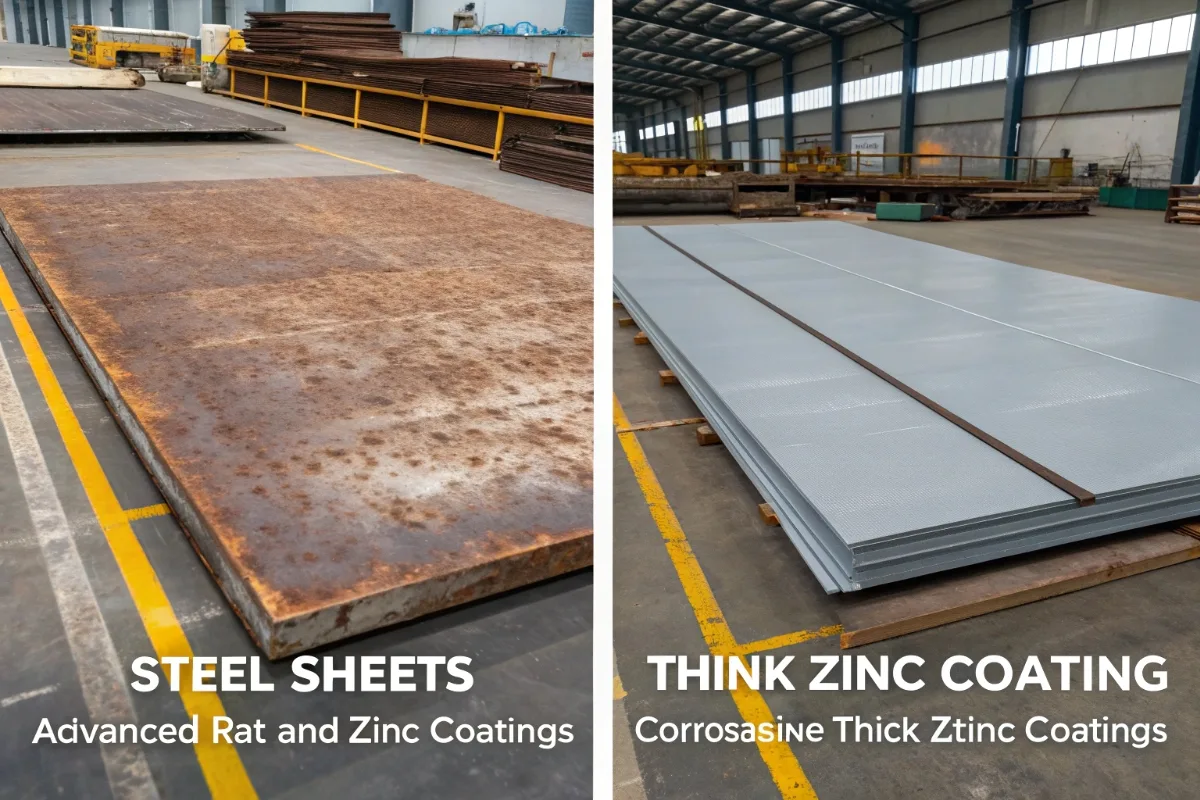

How Coating Thickness Affects Corrosion Resistance

Zinc protects steel by corroding first. A thicker zinc layer simply takes longer to be consumed, which means the underlying steel remains protected for a longer period. This relationship is close to linear: doubling the coating mass can nearly double the corrosion protection time under similar exposure conditions.

Thicker coatings also form more stable corrosion products, such as zinc carbonate, which slow further corrosion and enhance long-term durability.

Recommended Thickness for Different Environments

Environmental exposure determines how quickly zinc is consumed. In mild, dry inland climates, lighter coatings may perform adequately. However, in coastal, industrial, or high-humidity environments, thin coatings degrade rapidly.

For roofing, wall cladding, and outdoor structural applications in aggressive environments, heavier zinc or aluminum-zinc coatings are strongly recommended to ensure long service life and reduced maintenance.

How to Check Coating Quality Before Buying

Before purchasing steel coils, buyers should verify coating mass through mill test certificates and, when possible, physical inspection. Coating thickness gauges and third-party inspection reports provide additional assurance that the supplied material meets the specified standard.

Paying attention to coating thickness at the sourcing stage helps avoid premature corrosion, warranty disputes, and unexpected replacement costs later in the project lifecycle.

Conclusion

Zinc coating thickness is not a minor specification detail — it is a decisive factor in steel coil performance. Selecting coating mass based on real exposure conditions, rather than minimum compliance, ensures longer service life, lower maintenance costs, and better overall value.

For steel buyers and importers, understanding and specifying the right zinc coating thickness is one of the most effective ways to protect both the material and the investment behind it.