How Do You Choose the Right Finish for Color-Coated Steel Coils to Ensure Long-Term Performance?

Color-coated steel coils (also known as PPGI and PPGL) are widely used in construction, appliances, and industrial manufacturing. Choosing the right coating finish is crucial to ensure long-term durability, appearance, and protection against harsh environmental conditions. This guide explains how to choose the right finish to achieve long-lasting performance.

Table of Contents

- 1. Introduction to Color-Coated (PPGI/PPGL) Steel Coils and Their Uses

- 2. Comparing Coating Systems: Polyester, SMP, PVDF, and More

- 3. Key Factors to Evaluate Before Selecting a Color Coating

- 4. How Proper Maintenance Extends the Lifespan of Color-Coated Coils

1. Introduction to Color-Coated (PPGI/PPGL) Steel Coils and Their Uses

Color-coated steel coils are pre-painted galvanized (PPGI) or galvalume (PPGL) steel sheets that combine aesthetics with corrosion protection. They are widely applied in roofing systems, wall panels, home appliances, and decorative construction materials. These coils provide a durable, customizable surface finish that reduces the need for onsite painting.

2. Comparing Coating Systems: Polyester, SMP, PVDF, and More

The resin type used in the coating significantly affects performance:

- Polyester (PE): Cost-effective and suitable for general applications with moderate durability.

- Silicone-Modified Polyester (SMP): Improved gloss retention, chalk resistance, and weatherability.

- PVDF: Offers superior UV, color stability, and chemical resistance — ideal for extreme environments.

Other systems, such as high-durability FEVE or polyurethane coatings, are also available for specialized needs like coastal buildings or industrial plants.

3. Key Factors to Evaluate Before Selecting a Color Coating

Before choosing a coating system, consider the following aspects:

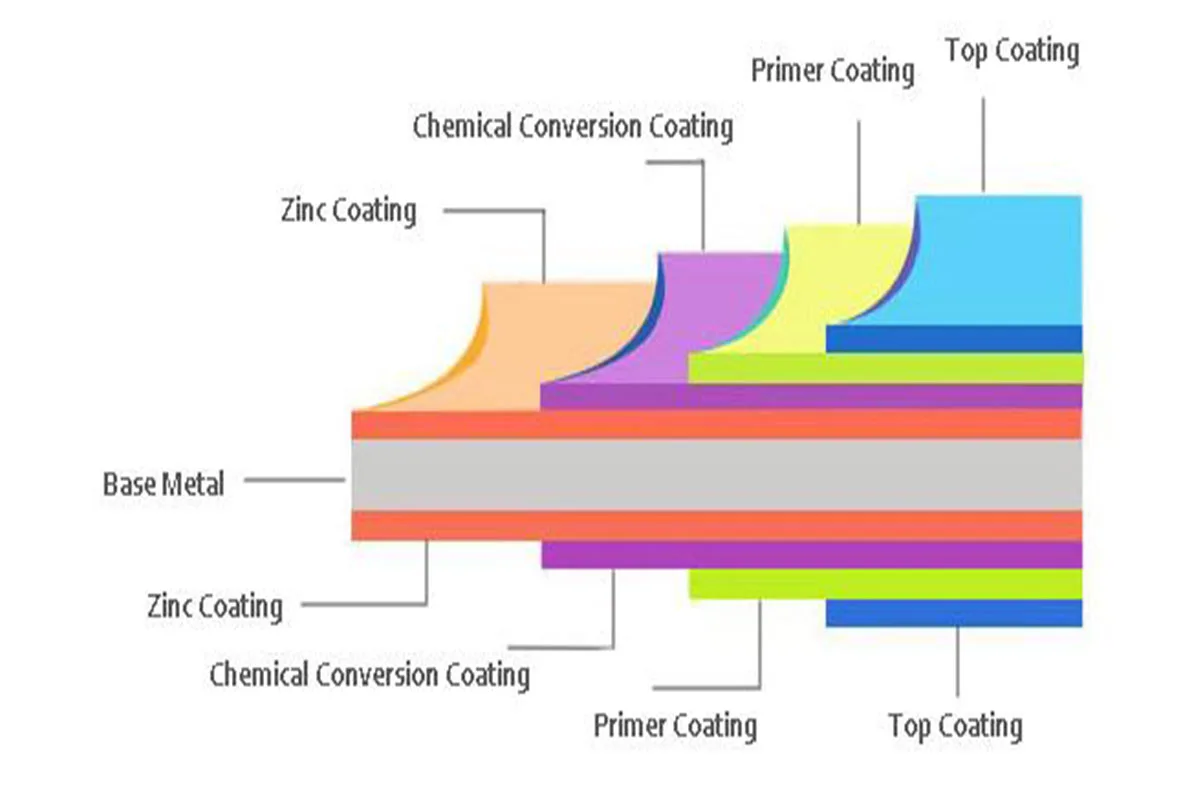

- Pre-treatment and primer quality: Good surface cleaning and primer adhesion prevent blistering and peeling.

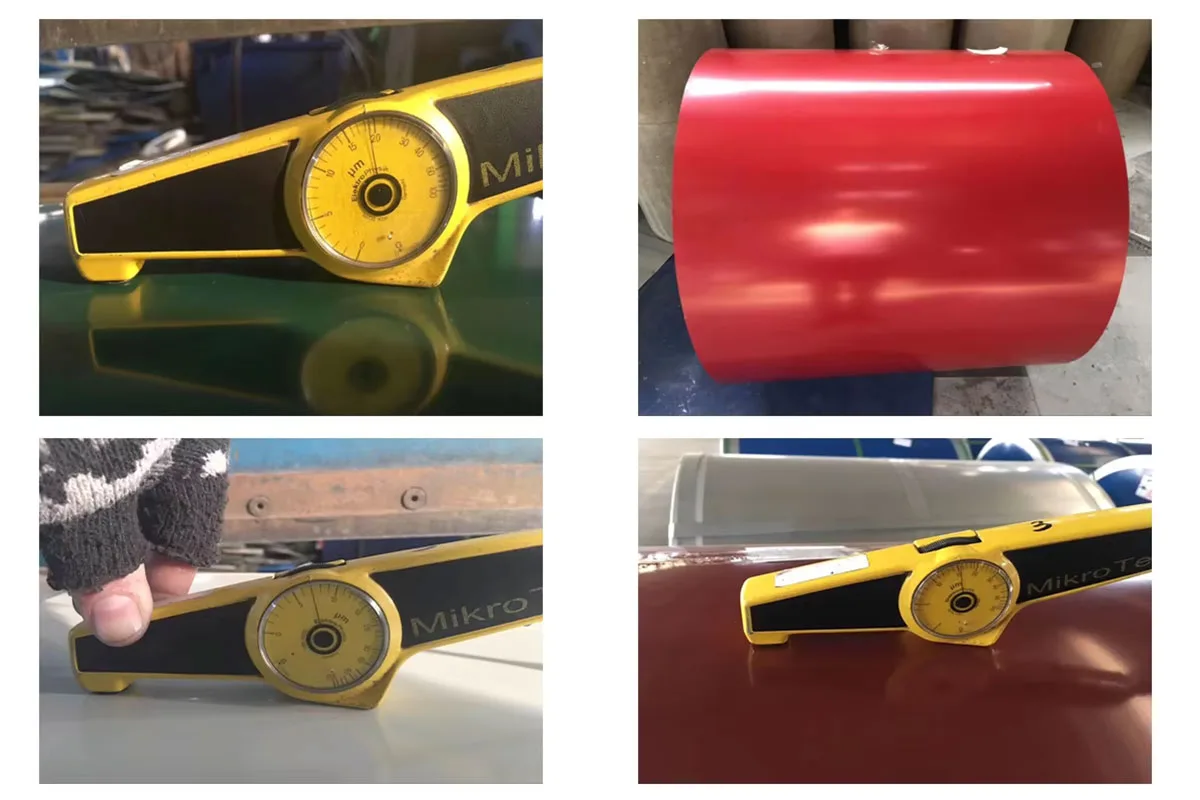

- Coating thickness: Thicker coatings resist wear better but may reduce flexibility if over-applied.

- Environmental exposure: UV radiation, humidity, salt spray, and acid rain all affect coating life.

- Formability: Coatings must remain flexible for bending or roll-forming without cracking.

- Thermal expansion match: A consistent CTE between layers reduces stress during temperature changes.

4. How Proper Maintenance Extends the Lifespan of Color-Coated Coils

Even the best coatings require regular maintenance. Dust, salt, or pollutants can degrade coatings over time. Periodic cleaning using mild detergents helps maintain appearance and prevents corrosion. For long-term protection, consider finishes with self-cleaning or hydrophobic properties that minimize dirt accumulation.

Conclusion

When selecting a finish for color-coated steel coils, consider the environment, coating system, and maintenance requirements. While PVDF or FEVE coatings come at a higher initial cost, they offer the best long-term performance and color stability for demanding conditions. Evaluating these factors ensures your project achieves both durability and visual appeal over time.