Table of Contents

- Introduction

- How Galvanized Steel Coils Are Made

- Key Advantages in Industrial Manufacturing

- Common Applications in Industry

- Claim

- Selecting the Right Coil Supplier

- Conclusion

Introduction

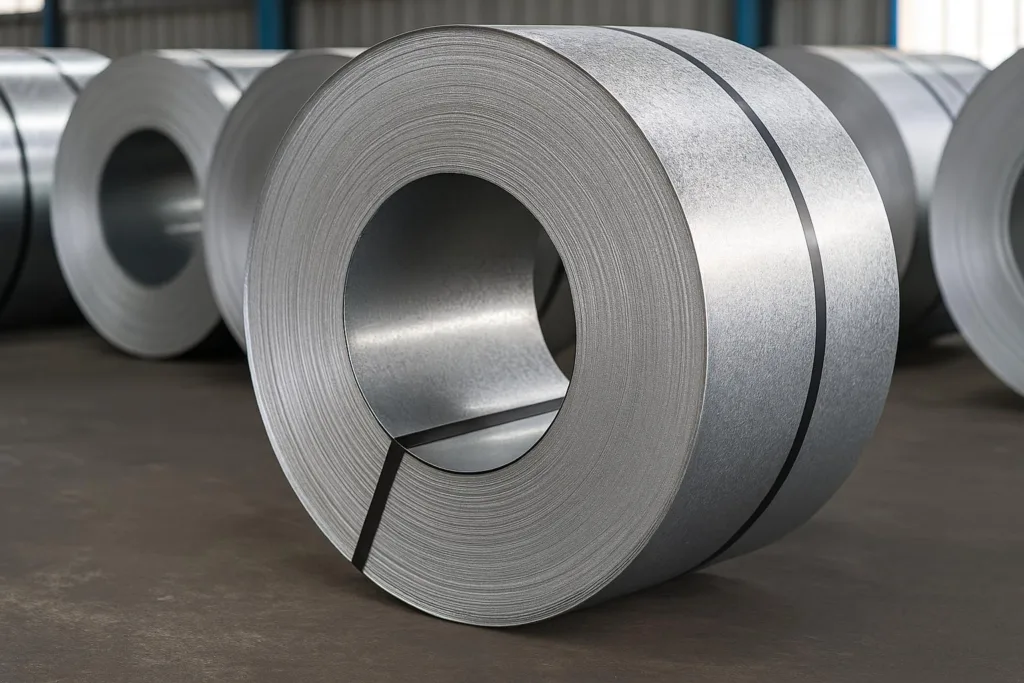

Galvanized steel coil is a critical material in today’s manufacturing world. Known for its corrosion resistance, mechanical strength, and cost-effectiveness, it plays an essential role in everything from automotive production to HVAC systems. This article explores how galvanized coils are produced, their key advantages, and why they’re an industrial standard worldwide.

How Galvanized Steel Coils Are Made

Galvanized steel coils are made by applying a protective zinc coating to cold-rolled steel. This can be done through:

– **Hot-dip galvanizing (HDG)**: Immersing the steel in molten zinc

– **Electro-galvanizing (EG)**: Using electric current to apply zinc

Common Specifications:

– Thickness: 0.2mm – 3.0mm

– Coating: Z40 – Z275

– Width: Up to 1250mm

– Surface: Regular/zero spangle, skin-passed, oiled or dry

Key Advantages in Industrial Manufacturing

1. Corrosion Resistance

The zinc layer protects the base metal from oxidation, making it ideal for both indoor and outdoor use.

2. Strength and Formability

Galvanized steel is strong yet flexible, making it suitable for bending, stamping, and deep drawing.

3. Cost-Effectiveness

Compared to stainless steel, it offers an affordable alternative with sufficient performance for most industrial needs.

4. Sustainability

Fully recyclable and long-lasting, galvanized steel supports sustainable development goals.

Common Applications in Industry

– **Automotive parts**: body panels, frames, chassis components

– **Construction**: HVAC ductwork, steel framing, roofing

– **Appliances**: washing machines, refrigerators, air conditioners

– **Agricultural equipment**: silos, grain bins, fencing

Claim: As global industries seek durable, scalable, and sustainable materials, galvanized steel coils remain a strategic pillar in the modern supply chain.

Claim

Galvanized steel coil provides the perfect balance of performance and cost-efficiency, making it indispensable to modern manufacturing systems.

Selecting the Right Coil Supplier

Choosing the right supplier ensures consistency, durability, and compliance. Key factors to evaluate:

– **Coating weight & uniformity**

– **Spangle control and surface finish**

– **Certifications**: ISO, ASTM A653, JIS G3302

– **Timely delivery and reliable quality assurance**

Conclusion

Galvanized steel coil continues to be the preferred solution for manufacturers who need durability, cost-efficiency, and excellent corrosion resistance. As industries move toward more sustainable and durable solutions, galvanized coil will remain at the heart of industrial progress.